Econo-Pak is the pioneer in contract food packaging services. With over 40 years of experience serving small businesses, Fortune 500 companies, and everything in between, we offer plenty of opportunities for growth and learning.

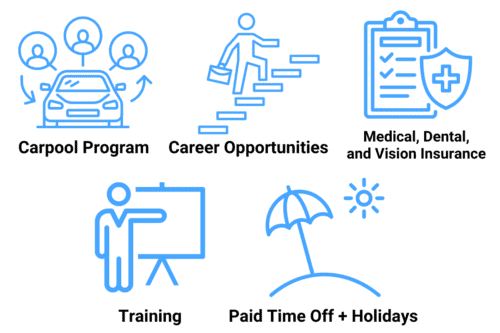

No matter whether you work in corporate or production, we offer an environment designed to help you grow your career. Just ask any of our staff who have been here for several years.

Our culture is positive, forward-looking, and obsessed with providing the best service to our customers every day.

We’re looking for happy and hardworking people who want to be a part of a fast-paced company in the food packaging industry. Check out our job openings below to apply with your resume and cover letter.

Job Openings

If no job openings are available but you would still like to inquire about a position, please visit our facility to speak with our staffing agency at 535 Route 6 and 209, Milford, PA 18337.