Choosing a Co-Packer for Allergen Foods

Millions of Americans have food allergies, and for those affected, the results of exposure can be life-threatening. Over the past few decades, the demand for allergen-specific foods in the U.S. and global markets has been growing.

Millions of Americans have food allergies, and for those affected, the results of exposure can be life-threatening. Over the past few decades, the demand for allergen-specific foods in the U.S. and global markets has been growing.

Co-packing is a game changer in today’s fast-paced market, speeding up product launch timelines. Manufacturers face various challenges, but co-packing with a provider like Econo-Pak offers a turnkey solution.

Co-packing is a game changer in today’s fast-paced market, speeding up product launch timelines. Manufacturers face various challenges, but co-packing with a provider like Econo-Pak offers a turnkey solution. Businesses always look for cost-effective yet innovative ways to grow their brand and enhance productivity. One way businesses often achieve this is through the use of a contract packager.

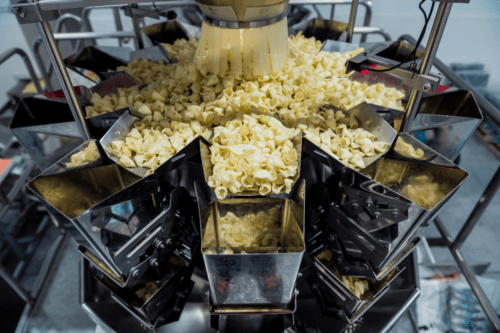

Businesses always look for cost-effective yet innovative ways to grow their brand and enhance productivity. One way businesses often achieve this is through the use of a contract packager.  Businesses in the food industry must be able to efficiently and consistently deliver high-quality products, which is where food co-packers can help. Food co-packers, or contract packagers, can help optimize your operations by improving efficiency, scaling production, and keeping food products consistent.

Businesses in the food industry must be able to efficiently and consistently deliver high-quality products, which is where food co-packers can help. Food co-packers, or contract packagers, can help optimize your operations by improving efficiency, scaling production, and keeping food products consistent. A co-packer, also known as a contract packer, is a company that packages products for other businesses. A co-manufacturer, or co-man, is a firm contracted to produce another company’s product line, often seen in the food industry. Outsourcing refers to the broader business practice of hiring external firms to perform services or create goods traditionally performed in-house by the company’s employees.

A co-packer, also known as a contract packer, is a company that packages products for other businesses. A co-manufacturer, or co-man, is a firm contracted to produce another company’s product line, often seen in the food industry. Outsourcing refers to the broader business practice of hiring external firms to perform services or create goods traditionally performed in-house by the company’s employees. Contract packaging, otherwise known as co-packing, involves outsourcing your product production, packaging, and sometimes even distribution to an expert partner. Let’s dive into the specifics of co-packing, including how it works, its many advantages, and how to get started.

Contract packaging, otherwise known as co-packing, involves outsourcing your product production, packaging, and sometimes even distribution to an expert partner. Let’s dive into the specifics of co-packing, including how it works, its many advantages, and how to get started.

Developing your own packaging system involves much more than investing in the right packaging equipment and materials to get the job done. It also involves warehousing and hiring an additional workforce to run your packaging operation alongside your core business.

Developing your own packaging system involves much more than investing in the right packaging equipment and materials to get the job done. It also involves warehousing and hiring an additional workforce to run your packaging operation alongside your core business. Growing your brand and ensuring your products get to your customers requires a reliable and timely production process. Contracting a co-packer can streamline the process for you.

Growing your brand and ensuring your products get to your customers requires a reliable and timely production process. Contracting a co-packer can streamline the process for you.