Expansion update: 125,000 square feet of new capacity coming soon

We’re only months away from completing the 125,000-square-foot expansion of our co-packing facility in Milford, PA! This new space will give us even more room to support high-volume food packaging projects for our clients.

Why Food Brands Use Different Oils to Season Their Products

The type of oil used to season a product can have just as much impact as the seasoning blend itself. While traditional oils like canola, soybean, and palm have long been the industry standard, more brands are now turning to alternative oils—like avocado oil—to meet evolving consumer preferences.

Red Flag: When your co-packer asks you to pay for their equipment

When you’re scaling a food product, working with the right co-packer can unlock growth, simplify operations, and help you break into major markets. But not all co-packers operate the same way. One of the biggest warning signs? Being asked to fund equipment just to get started.

Food Allergen Management in Co-Packing Operations

Managing food allergens is a critical component of every successful co-packing operation. With the growing demand for allergen-free and clean-label products, food brands rely on their contract manufacturers to uphold strict allergen management protocols that protect consumers and maintain brand integrity.

Retail Co-Packing 101: What Food Brands Need to Know to Succeed in Retail

A retail co-packer serves as a bridge between production and retail shelves. Their expertise lies in packaging products efficiently while adhering to industry standards. Co-packers help businesses convert raw materials into retail-ready packages, streamlining the journey from factory to customer.

The Smart Way to Manage Airline Co-Packing, Imports, and Tariff Challenges

Supply chains have become increasingly complex. Food brands must stay ahead of shifting regulations, evolving import strategies, and airline-specific requirements. With Econo-Pak, they can.

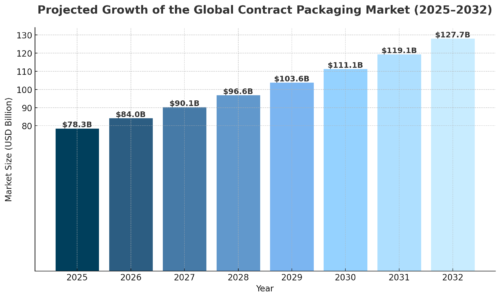

The Unstoppable Growth of Contract Food Packaging and Private Labeling

Consider this: the global contract packaging market is projected to reach $102 billion by 2028, growing at a 7% CAGR, as more companies lean on experts to streamline operations and reduce costs.

Meeting Airline Audit Standards for In-Flight Snack Co-Packing

For food brands selected to supply airline snack programs, partnering with a co-packer that meets airline standards is critical. That’s why Econo-Pak is regularly audited and approved by all major U.S. airlines.

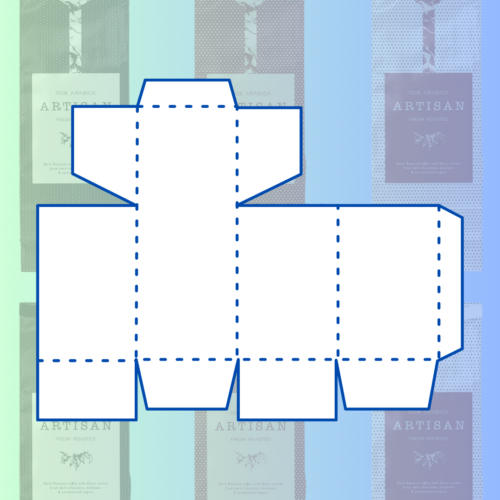

Importance of Dielines in Quoting Co-Packing Projects

One of the most critical factors in providing an accurate co-packing quote is the dieline. Without it, pricing and feasibility assessments become challenging, often leading to delays, cost discrepancies, or unexpected production issues.

Finding the Right Candy Co-Packer: What Brands Need to Know

Finding the Right Candy Co-Packer: What Brands Need to Know The candy industry is evolving, with brands looking for efficient, scalable ways to bring their products to market. Whether launching a new line of gummies, chocolates, or hard candies, partnering

Navigating Food Safety Certifications: What Food Brands Need to Know Before Entering Retail

Here’s what food companies need to know when preparing for FDA registration, kosher and halal certification, and USDA organic approval.

Co-Packing for Organic and Non-GMO Food Products

Co-packing plays a pivotal role in the food industry, especially for brands focused on organic and non-GMO products. According to the Organic Trade Association, sales of organic food in the U.S. grew by 12.4% in 2020, reaching a record $62 billion, while demand for non-GMO products continues to rise as consumers prioritize transparency and health (Organic Trade Association, 2021).