Red Flag: When your co-packer asks you to pay for their equipment

When you’re scaling a food product, working with the right co-packer can unlock growth, simplify operations, and help you break into major markets. But not all co-packers operate the same way. One of the biggest warning signs? Being asked to fund equipment just to get started.

From Cartons to Cost Savings: Food Co-Packing Procurement

In this episode of the Econo-Pak Podcast, Director of Procurement Tim joins Sarah to talk through how procurement supports scalable, efficient co-packing solutions.

How Flexible Equipment Powers Scalable Co-Packing with Jared Ellsworth

In this conversation, Jared Ellsworth, Maintenance Manager at Econo-Pak, shares how our facility stays ahead by using versatile machinery, smart automation, and efficient changeovers to support high-volume food brands.

Food Allergen Management in Co-Packing Operations

Managing food allergens is a critical component of every successful co-packing operation. With the growing demand for allergen-free and clean-label products, food brands rely on their contract manufacturers to uphold strict allergen management protocols that protect consumers and maintain brand integrity.

Retail Co-Packing 101: What Food Brands Need to Know to Succeed in Retail

A retail co-packer serves as a bridge between production and retail shelves. Their expertise lies in packaging products efficiently while adhering to industry standards. Co-packers help businesses convert raw materials into retail-ready packages, streamlining the journey from factory to customer.

How Econo-Pak’s New Bag-in-Box Automation Boosts Co-Packing Efficiency

Econo-Pak recently invested in new bagging and cartoning machines—designed to streamline the packaging process for dry food products like rice, baking mixes, powders, and more in a bag-in-box format.

The Smart Way to Manage Airline Co-Packing, Imports, and Tariff Challenges

Supply chains have become increasingly complex. Food brands must stay ahead of shifting regulations, evolving import strategies, and airline-specific requirements. With Econo-Pak, they can.

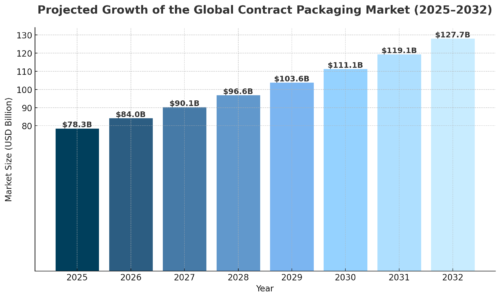

The Unstoppable Growth of Contract Food Packaging and Private Labeling

Consider this: the global contract packaging market is projected to reach $102 billion by 2028, growing at a 7% CAGR, as more companies lean on experts to streamline operations and reduce costs.

Meeting Airline Audit Standards for In-Flight Snack Co-Packing

For food brands selected to supply airline snack programs, partnering with a co-packer that meets airline standards is critical. That’s why Econo-Pak is regularly audited and approved by all major U.S. airlines.

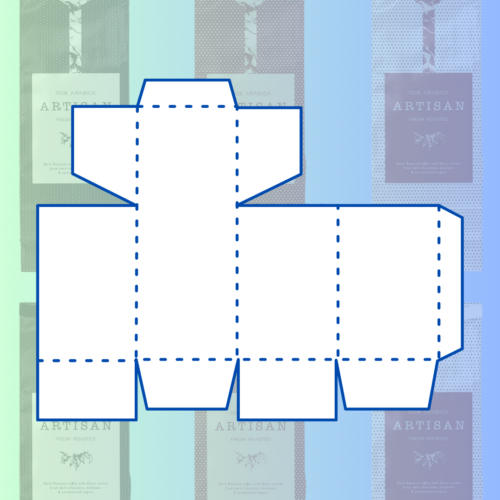

Importance of Dielines in Quoting Co-Packing Projects

One of the most critical factors in providing an accurate co-packing quote is the dieline. Without it, pricing and feasibility assessments become challenging, often leading to delays, cost discrepancies, or unexpected production issues.

Finding the Right Candy Co-Packer: What Brands Need to Know

Finding the Right Candy Co-Packer: What Brands Need to Know The candy industry is evolving, with brands looking for efficient, scalable ways to bring their products to market. Whether launching a new line of gummies, chocolates, or hard candies, partnering

Navigating Food Safety Certifications: What Food Brands Need to Know Before Entering Retail

Here’s what food companies need to know when preparing for FDA registration, kosher and halal certification, and USDA organic approval.