Shrink Wrapping

Shrink wrapping offers a sleek, secure packaging solution for bundling multiple items, widely favored for its quality and affordability. It involves wrapping products of any size or shape in a plastic film, which is then heated to snugly fit the item’s contours.

Econo-Pak excels in providing comprehensive shrink-wrapping services across various industries, with a vast 240,000-square-foot facility ready to handle orders of any scale. We pride ourselves on our process efficiency, ensuring timely deliveries from single items to large-scale production runs.

Our services cater to high-volume projects, leveraging over 200 cutting-edge packaging machines for fast, high-quality shrink wrapping at great value. Shrink film comes in various shrink ratios, thicknesses, and clarities to meet different packaging needs, ensuring the right balance between durability and visual appeal.

Benefits of Shrink Wrapping

The shrink wrapping process involves a film, a sealer, and a heating element. Clients choose their preferred plastic type—typically polyolefin, PVC, or polyethylene—before products undergo a system that wraps, seals, and applies heat for a perfectly contoured package.

This packaging method comes with many benefits, which include:

Increased security: Shrink wrapping increases the security of the package, keeps the contents together, allows visibility of the existing marketing print, and improves the cleanliness of the project on the shelf.

Increased security: Shrink wrapping increases the security of the package, keeps the contents together, allows visibility of the existing marketing print, and improves the cleanliness of the project on the shelf.

Improved flexibility: Shrink wrapping can work with uniquely shaped products, and it can accommodate a virtually unlimited range of product sizes.

Improved flexibility: Shrink wrapping can work with uniquely shaped products, and it can accommodate a virtually unlimited range of product sizes.

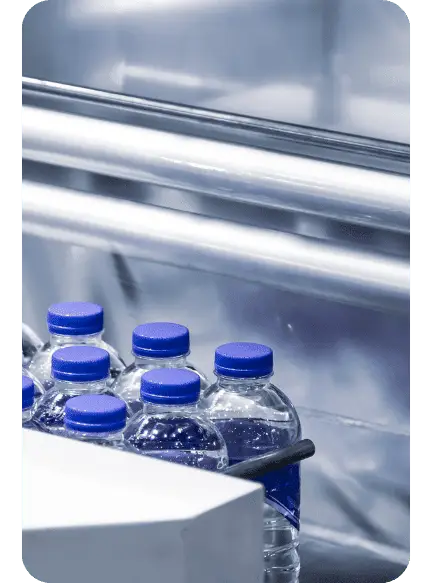

High product quality: We use the highest-grade shrink wrapping films that meet or exceed all industry standards (including those that apply to food and beverage products). Our shrink-wrapped film packages are also completely ready for use in retail environments.

High product quality: We use the highest-grade shrink wrapping films that meet or exceed all industry standards (including those that apply to food and beverage products). Our shrink-wrapped film packages are also completely ready for use in retail environments.

Versatility: We work around the clock in three production shifts to accommodate the tightest deadlines. Our shrink lines can handle extra-long product lengths as well as objects with sensitive electronics or components.

Versatility: We work around the clock in three production shifts to accommodate the tightest deadlines. Our shrink lines can handle extra-long product lengths as well as objects with sensitive electronics or components.

Affordability: Shrink wrap offers a much more affordable alternative over other materials used for packaging. Effective use of shrink wrap can also minimize space by keeping items bundled closely together without the use of additional bulky materials like boxes.

Affordability: Shrink wrap offers a much more affordable alternative over other materials used for packaging. Effective use of shrink wrap can also minimize space by keeping items bundled closely together without the use of additional bulky materials like boxes.

FDA compliance: Shrink wrap can be used to package many food and beverage products. Shrink packaging can be built to conform to FDA and third-party regulations and preserve the freshness of its contents.

FDA compliance: Shrink wrap can be used to package many food and beverage products. Shrink packaging can be built to conform to FDA and third-party regulations and preserve the freshness of its contents.

Customization potential: Shrink wrap can include colors, words, pictures, and logos that enhance your brand’s appeal. From the production floor to the end user, your product isn’t just wrapped in plastic—it’s wrapped in your brand.

Customization potential: Shrink wrap can include colors, words, pictures, and logos that enhance your brand’s appeal. From the production floor to the end user, your product isn’t just wrapped in plastic—it’s wrapped in your brand.

Using polymer plastic film to tightly wrap any product, shrink wrapping can work with a wide range of items.

Industry-Leading Shrink Wrapping Service Experts

Industry-Leading Shrink Wrapping Service Experts

To learn more about our shrink wrapping services or to request a custom quote for your project, contact us directly today.

Nearly every major market that uses shrink wrap has done so through us. We’ve worked with clients from a wide range of industries to shrink wrap products that appear in:

- Supermarkets

- Club stores

- Convenience stores

- Vending machines

- Food service and hospitality environments

- E-commerce brands

With an HACCP-based quality-control system that fully complies with all FDA regulations, our shrink-wrapping services meet the industry’s highest quality standards.

We can also specifically design our services to comply with the following certifications:

- Certified organic

- Safe Quality Food (SQF) Level 3

- Kosher/Halal

- Gluten free

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.